Control element for high voltage power supplies

(Rev D5)

| Features | Applications |

| ? 5 V Control | ? Photoelectron Microscopy |

| ? 8 kV Bias Voltage | ? Electrostatic Deflection Plates |

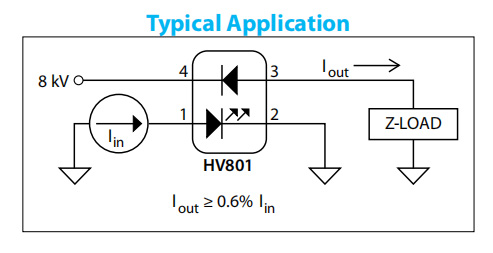

| ? Current Transfer Ratio ≥0.6% | ? Space instrumentation |

| ? Low Leakage Current | ? Electrostatic analyzers |

| ? 12 kV Isolation Voltage | ? High voltage power supplies |

| ? Radiation Tolerant to 105 rad(Si) | ? Regulated current source |

| ? Up to 100 V/μs slew rate (10 pF load) | ? High Voltage relay |

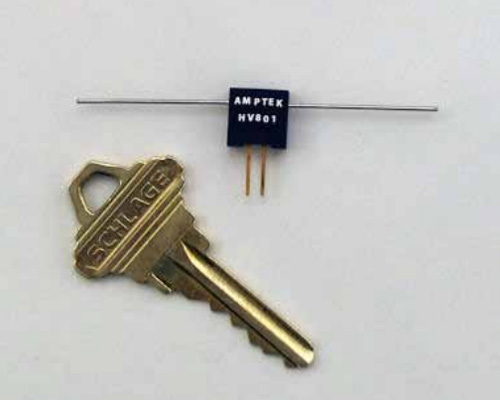

| ? Small footprint | ? High Voltage bipolar amplifier |

| ? Backward compatible to HV601B | |

General Description

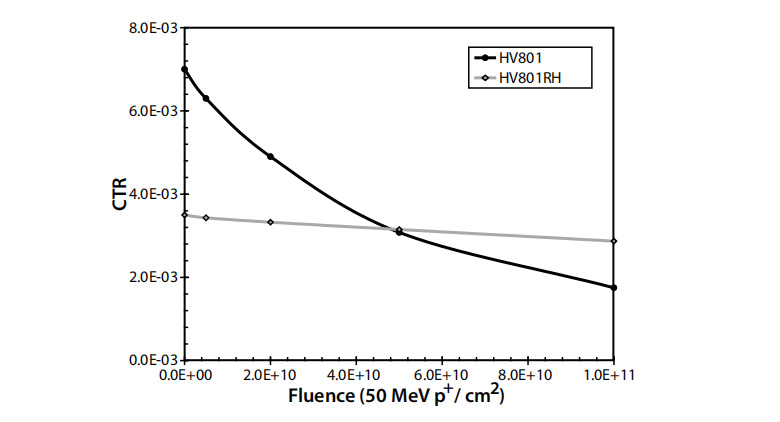

Amptek offers an HV801RH, or rad-hard, option. The light output of LEDs is well known to decrease with displacement damage, i.e., due to penetrating protons in space. The RH option uses an alternate LED, which has a lower initial light output but which decreases more slowly with proton fluence. The HV801RH CTR is >0.2%. The two parts are otherwise identical.

| Input Current: Continuous Pulse (10 μs, 100 Hz) | 100 mA 1 A |

| Input Reverse Voltage | 5 V |

| Junction Temperature | 100 °C |

| Output Bias Voltage | 8 kV |

| Operating Temperature (See Thermal Considerations next page) | -35 °C to +100 °C |

| Storage Temperature | -35 °C to +100 °C |

Stress above those listed under Absolute Maximum Ratings may cause permanent damage to the device. Exposure to absolute maximum conditions for extended periods may affect device reliability.

| Parameter | Symbol | Conditions | Min. | Typ. | Max. | Units |

| Reverse Breakdown Voltage | VBR | ID = 1 μA | >10.0 | | | kV |

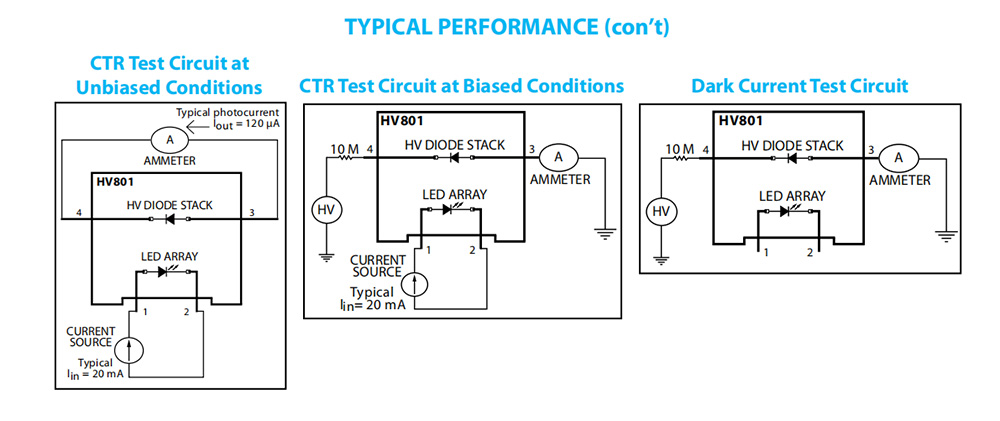

| Current Transfer Ratio HV801 HV801 HV801RH HV801RH | CTR | Iin = 20mA, Vbias = 0V Iin = 20mA, Vbias = 6kV Iin = 20mA, Vbias = 0V Iin = 20mA, Vbias = 6kV | 0.6 0.2 | 1.6 0.8 | | % % % % |

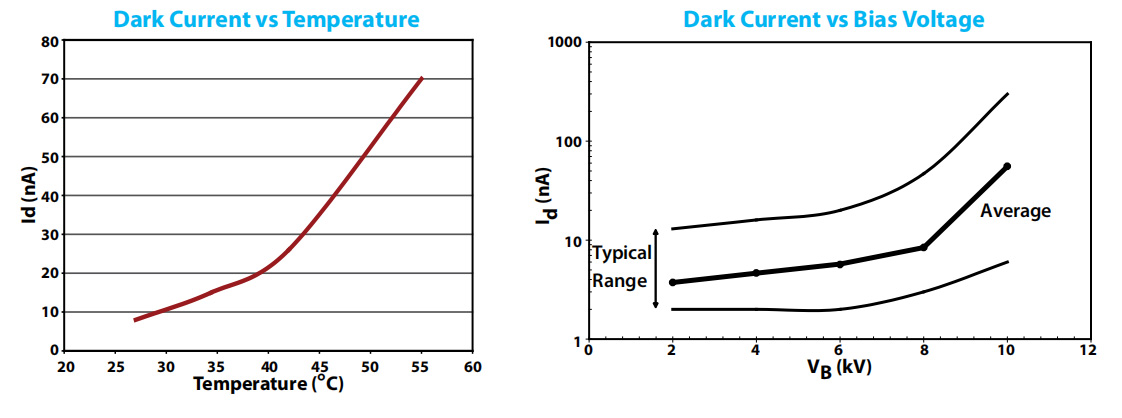

| Dark Current | I D | VB = 8 kV | | 10.0 | 250 | nA |

| Output Capacitance | CO | VJ = 0 V | | 8.0 | | pF |

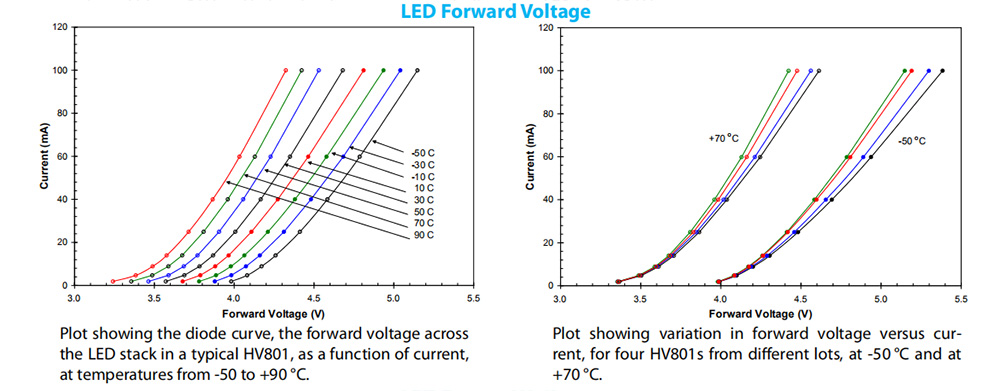

| Input Voltage | Vin | I IN = 20 mA | | 4.0 | | V |

| Isolation Capacitance | CISO | | | 0.6 | | pF |

| Isolation Voltage | VISO | | 12.0 | | | kV |

| 1. | Nondestructive Bond Pull (100%) | MIL-STD-883, Method 2023 |

| 2. | Visual Inspection | MIL-STD-883, Method 2017 |

| 3. | Encapsulation | Low outgassing epoxy package |

| 4. | Marking | Serial Number, Date Code, ID |

| 5. | Electrical Test | At +25 °C |

| 6. | Temperature Cycling | MIL-STD-883, Method 1010, (modified) T = -35 °C to 100 °C, 15cycles, 4 min. each extreme, 3 min.maximum transfer time |

| 7. | Electrical Test | At +25 °C |

| 8. | Radiographic | MIL-STD-883, Method 2012 |

| 9. | Burn-in | MIL-STD-883, Method 1015, 320 hrs @ 90 °C |

| 10. | Final Electrical Test | At +80 °C, +25 °C and -35 °C |

| QC Periodic Tests | ||

| 11. | Life Test on sample devices | 1000 hours (total) Burn-In at +90 °C with additional interim and Final Electrical Tests at +80 °C, +25 °C and -35 °C |

| 12. | Temperature Cycling | 100 cycles as in step number six above |

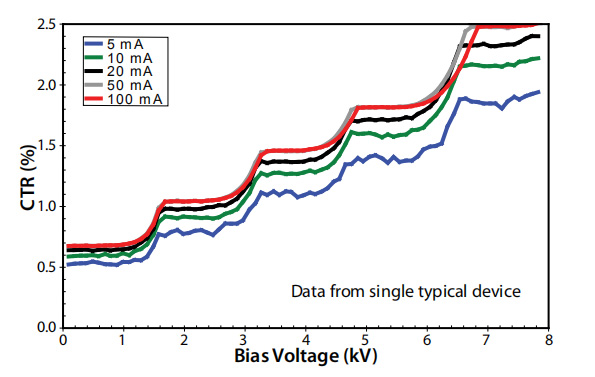

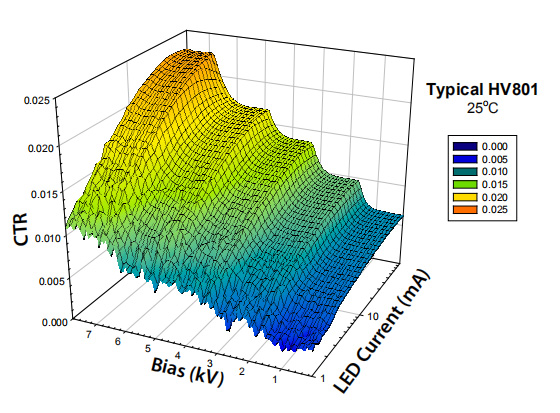

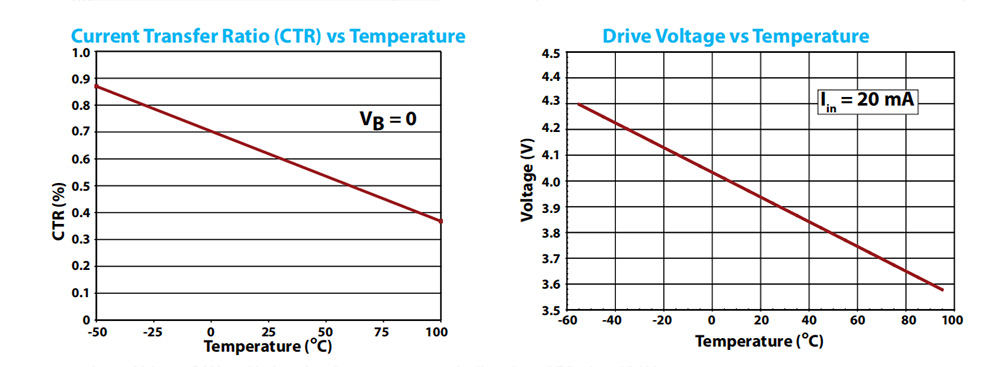

As these plots show, the Current Transfer Ratio (CTR) increases as a function of input current and bias voltage and decreases with increasing temperature. The CTR of each HV801 is measured by Amptek to be >0.6% at ILED =20 mA, no bias voltage, and at 25 °C.

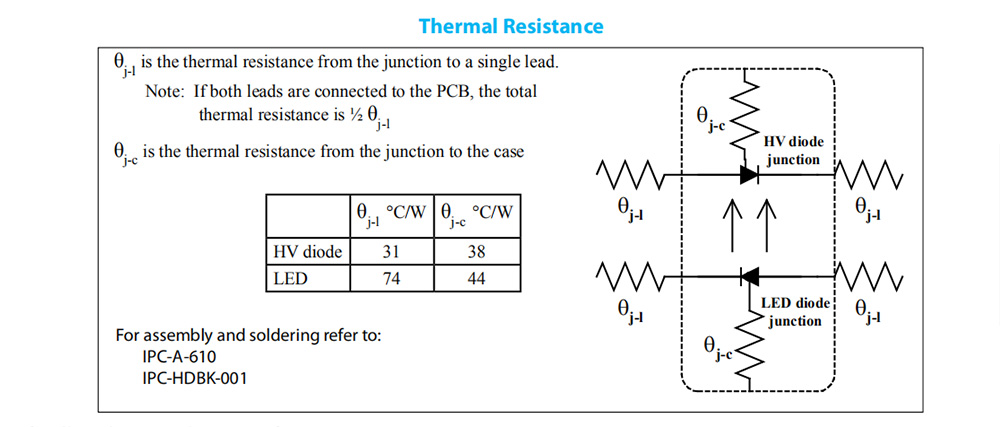

The CTR is not a linear or even a smooth function of bias or current. Because the HV801 is in the feedback loop, this is not important. Nonlinear devices, such as transistors, are commonly used for feedback. The circuit designer must insure that the loop has enough gain, under the worst case conditions, to meet the accuracy requirements.The detailed variation of the CTR with the various parameters is generally not critical because of its location in the

Note that the CTR is a function of bias voltage, current, temperature, and exhibits

manufacturing variability. The user must examine all these parameters closely if operation near the maximum junction temperature is anticipated.

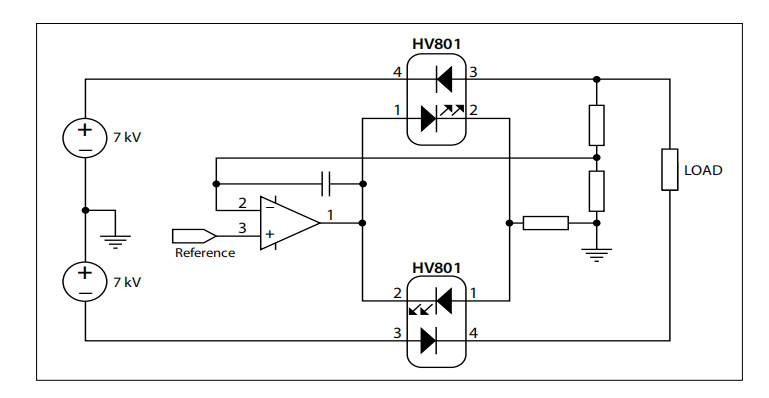

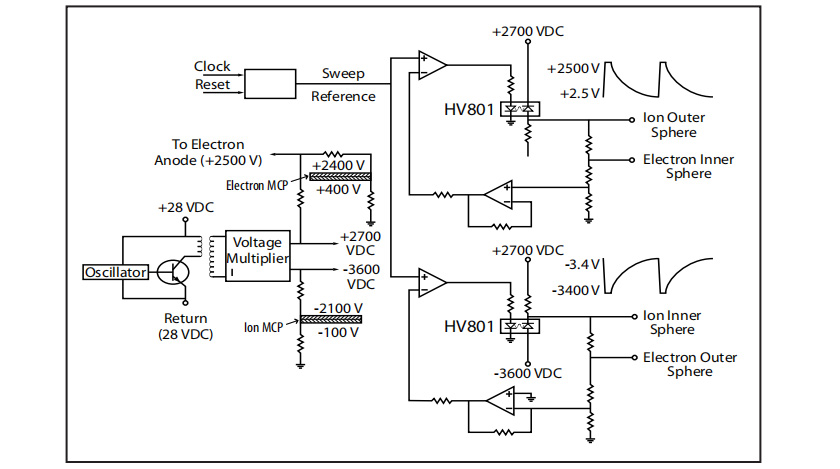

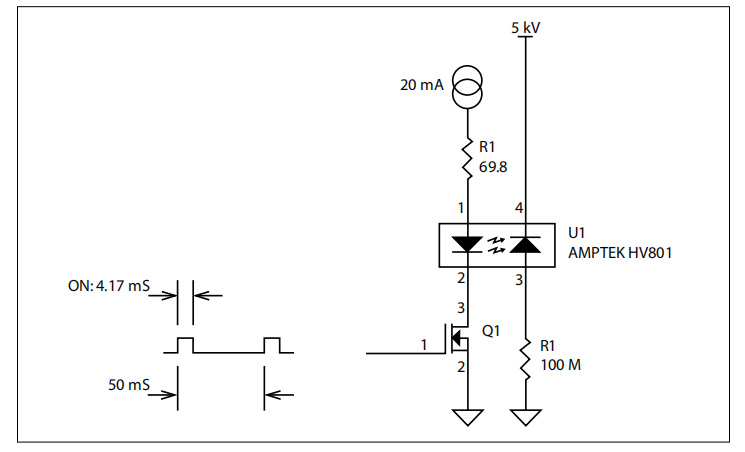

This calculation, though simple, does not represent the typical usage of an HV801. An HV801 is most often used to control rapidly a stepped voltage, i.e., biasing the deflection

electrodes in an electrostatic analyzer. The current only flows for a brief period at the beginning of each step, i.e., there is a very low duty cycle. The total power dissipation is reduced greatly. Typical applications exhibit tens of mW of total power.

APPLICATIONS for HV801

微信二維碼

微信二維碼