The FAST SDD? represents Amptek’s highest performance silicon drift detector (SDD), capable of count rates over1,000,000 CPS (counts per second) while maintaining excellent resolution. The FAST SDD? is also available with our C-Series (Si3N4) low energy windows for soft x-ray analysis.

Amptek recently brought silicon wafer manufacturing in-house and improved the process. The result is a detector with lower noise, lower leakage current, better charge collection, and uniformity from detector to detector. This makes it the best performing silicon drift detector available and the true state-of-the-art.

The FAST SDD? represents Amptek’s highest performance silicon drift detector (SDD), capable of count rates over 1,000,000 CPS (counts per second) while maintaining excellent resolution. The FAST SDD? is also available with our C-Series (Si3N4) low energy windows for soft x-ray analysis.

Features

Applications

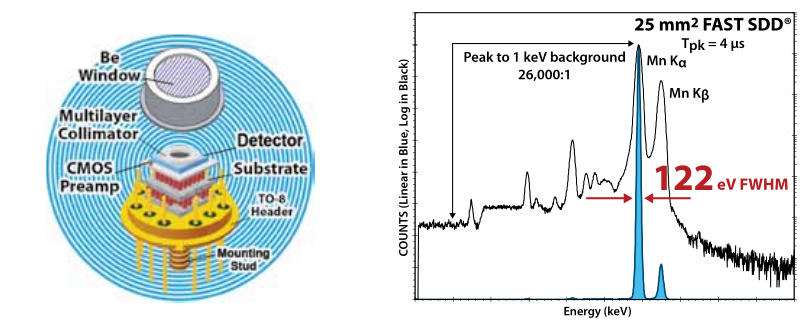

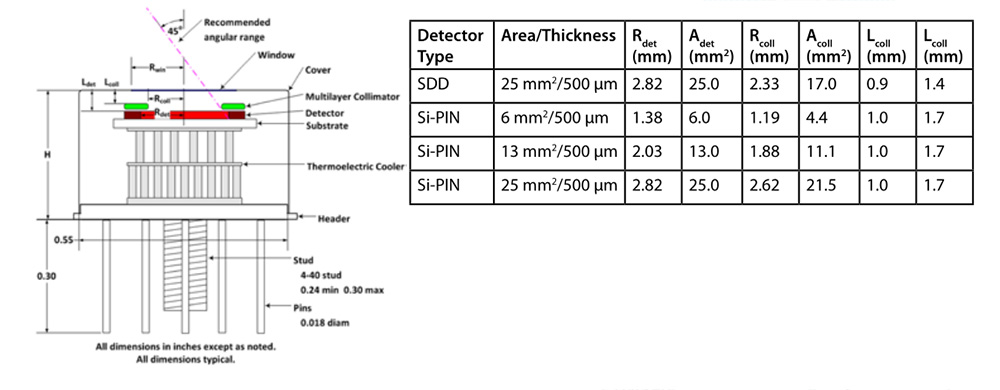

? 25 mm2 active area collimated to 17 mm2

? Ultra-fast benchtop and handheld XRF analyzers

? Also available 70 mm2 collimated to 50 mm2

? Scanning/mapping of samples in an SEM as part of an EDS system

? 122 eV FWHM resolution at 5.9 keV

? On-line process control

? Count rates > 1,000,000 CPS

? X-Ray Sorting Machines

? High peak-to-background ratio – 26,000/1

? OEM

? Preamplifier Output Rise Time <35 ns

? Windows: Be (0.5 mil) 12.5 μm, or C Series (Si3N4)

? Radiation hard

? Detector thickness 500 μm

? TO-8 Package

? Cooling ΔT>85 K

? Multilayer Collimator

The True State-of-the-Art

? Lower noise ? Better resolution down to 122 eV FWHM

? Lower leakage current ? Higher temperature operation (save battery life)

? Better charge collection ? Better photopeak shape (no tailing)

? Quality ? Detectors have consistent performance allowing for easier calibrations

Overview

Unlike our conventional SDDs which use a junction gate field-effect transistor (JFET) inside the hermetically sealed TO-8 package, along with an external preamplifier, the FAST SDD uses a complementary metal-oxide-semiconductor (CMOS) preamplifier inside the TO-8 package, and replaces the JFET with a metal-oxide-semiconductor field-effect transistor (MOSFET). This significantly reduces capacitance, providing much lower series noise and yielding improved resolution at very short peaking times. The FAST SDD? uses the same detector but with a preamplifier giving lower noise at short peaking times. Improved (lower) resolution enables isolation/separation of fluorescent X-rays with close energy values where peaks would otherwise overlap, permitting users better identification all of the elements in their sample(s). Short peaking times also yield significant improvements in count rates; more counts provide better statistics.

Specifications

General

Detector Type

Silicon Drift Detector (SDD) with CMOS preamplifier

Detector Size

25 mm2 - collimated to 17 mm2 Also available 70 mm2 - collimated to50 mm

Silicon Thickness

500 μm

Collimator

Internal Multilayer Collimator (ML)

Energy Resolution@ 5.9 keV ( 55 Fe)

122 - 129 eV FWHM at 4 μs peaking time (guaranteed)

Peak to Background

20000:1 (ratio of counts from 5.9 keV to 1 keV) (typical)

Detector Window Options

Beryllium (Be): 0.5 mil (12.5 μm or 0.3

mil (8 μm)

C Series (Si3N4) Low energy windows

Charge Sensitive Preamplifier

CMOS

Gain Stability

<20 ppm/°C (typical)

Size

Detector Module

XR100 Box

X-123 Box

OEM

TO-8 package (0.640 in. high including pins, 0.600 in. diameter)

3.00 x 1.75 x 1.13 in (7.6 x 4.4 x 2.9 cm)

3.94 x 2.67 x 1.0 in (10.0 x 6.78 x 2.54 cm )

Configurations vary

Weight

Detector Module

XR100 Box

X-123 Box

OEM

0.14 ox (4.1 g)

4.4 oz (125 g)

6.3 oz (180 g )

Configurations vary

Total Power

<2 Watt

Warranty Period

1 Year

Device Lifetime

Typical 5 to 10 years, depending on use

Operation conditions

-35°C to +80°C

Long-term Storage

10+ years in dry environment

Typical Storage & Shipping

-40°C to +85°C, 10 to 90% humidity noncondensing

TUV Certification

Certificate #: CU 72072412 02

Tested to: UL 61010-1: 2004 R7 .05

CAN/CSA-C22.2 61010-1: 2004

XR-100SDD Inputs

Preamp Power

XR100 configuration: ±8 V @ 15 mA with no more than 50 mV peak-to-peak noise

OEM configuration (PA210/230 or X-123): ±5 V

Detector Power

-100 to -180 V @ 25 μA, very stable <0.1% variation

Cooler Power

Current

Voltage

450 mA maximum

3.5 V maximum with <100 mV peak-to-peak noise

Note: The XR-100SDD includes its own temperature controller

Outputs

Preamplifier

Sensitivity

Polarity

Feedback

3.6 mV/keV typical (may vary for different detectors)

Positive signal output (1 k? max. load)Reset

Temperature Monitor Sensitivity

Varies with configuration

When used with PX5, DP5, or X-123:

direct reading in Kelvin through software.

Preamplifier Output Rise Time

<35 ns

Performance

Performance

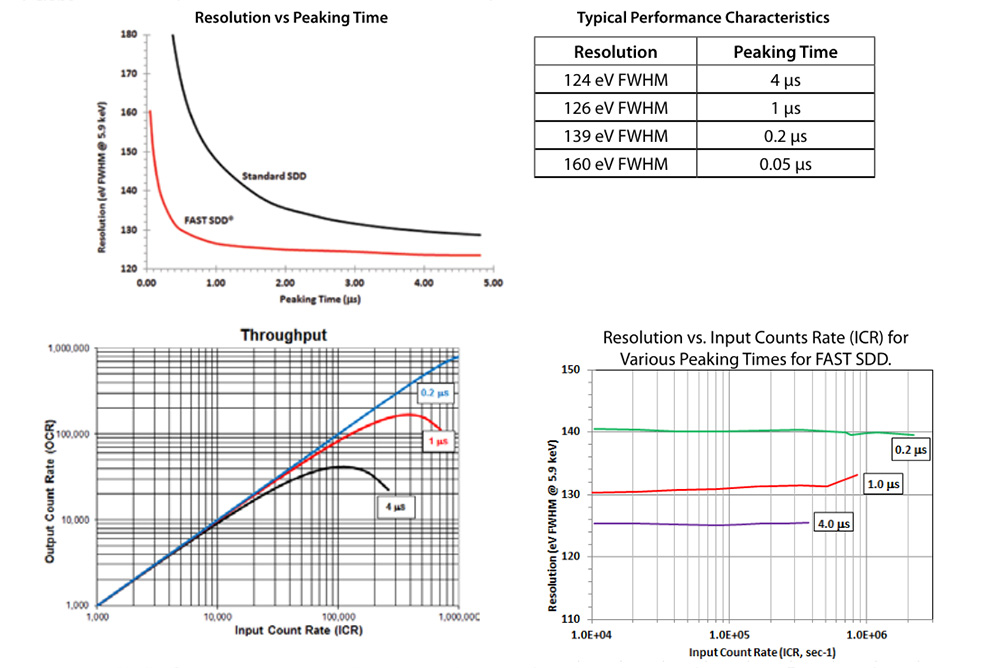

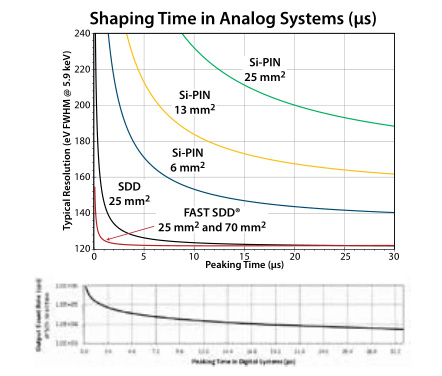

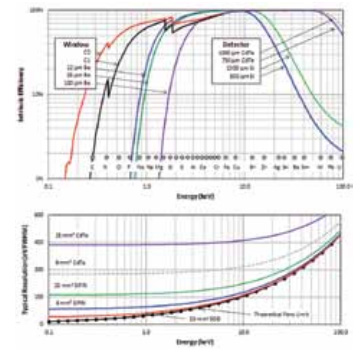

Energy Resolution and Count Rate: This plot shows how the energy resolution at 5.9 keV is related to the output count rate for Amptek’s X-ray detectors, as a function of the pulse shaping time and the equivalent peaking time in a digital processor. These are typical values at full cooling (220K).

For example, at a T peak of 9.6 microseconds (equivalent to 4.0 microsecond pulse shaping time) the output count rate at 50% dead time is 18 kcps.

This is a function only of the pulse processing so is the same for all detectors. The energy resolution for a 6 mm 2 Si-PIN is just under 160 eV FWHM while for a 25 mm 2 SDD it is 130 eV FWHM.

In the bottom plot, the black curve represents “Fano broadening”, the theoretical limit with a Si based detectors, arising from quantum fluctuations in the charge production process. The colored curves represent the combination of Fano broadening and intrinsic electronic noise under optimum conditions (full cooling and long peaking time). The detector selection is most important at the lowest energies because Fano broadening dominates at high enough energies.

In the top plot, the efficiency at low energies is determined by transmission through the window and detector dead layer. The efficiency at high energies is determined by attenuation in the active depth of the detector. A Si detector with Be window is recommended between about 2 and 30 keV. A Si detector with a C1 or C2 window is recommended at lower energies, while a CdTe detector is best at energies above 30 keV.

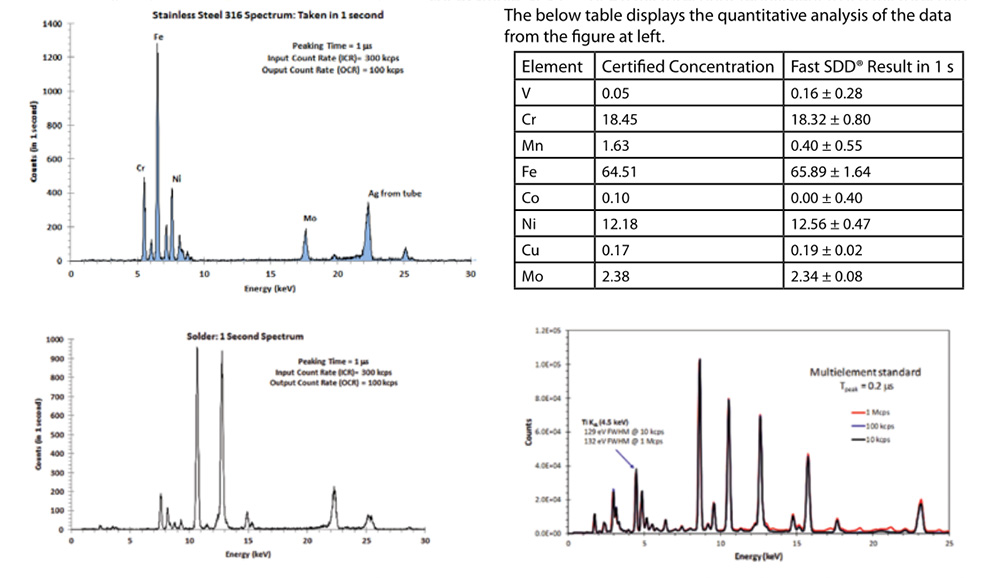

Application Spectra

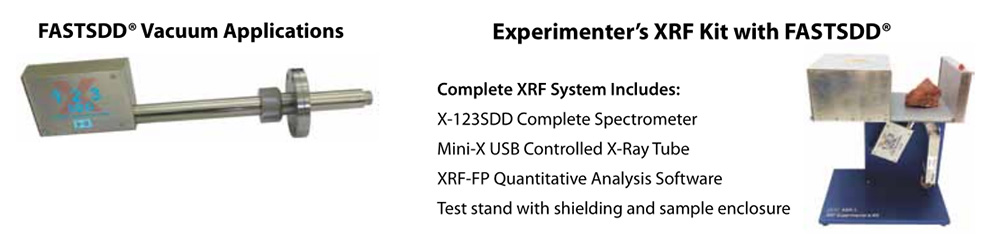

Configurations

X-123FASTSDD?

OEM FASTSDD?

XR-100FASTSDD?

微信二維碼

微信二維碼